EdgeTec Roll-Up Machines

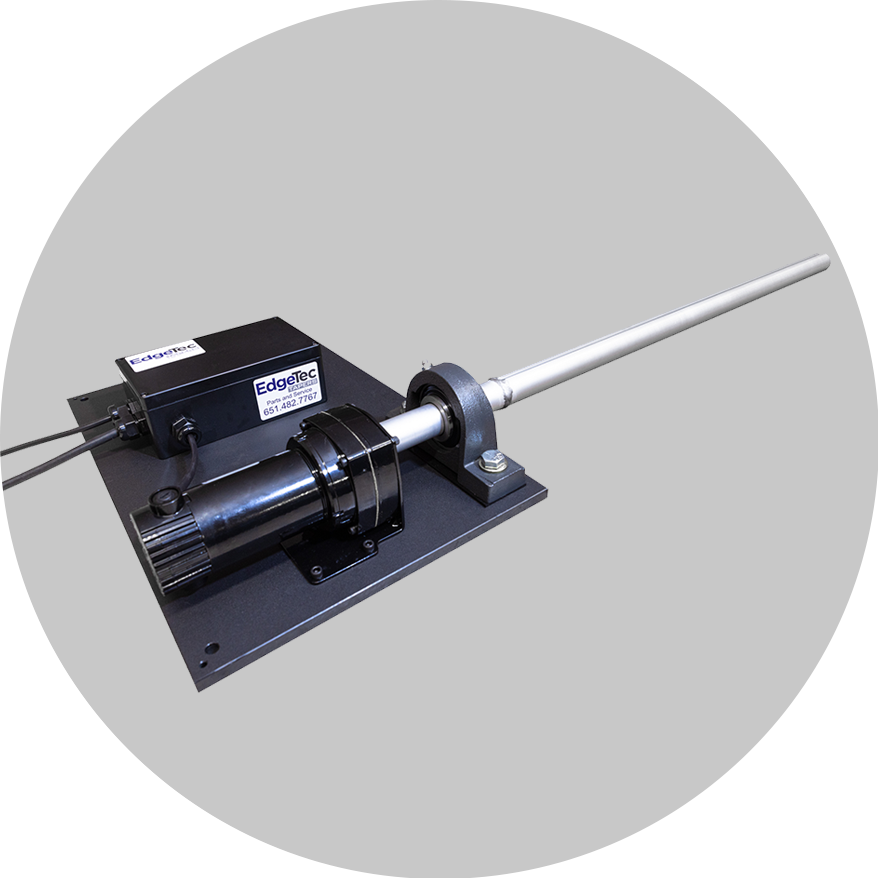

EdgeTec Roll-Up Lite

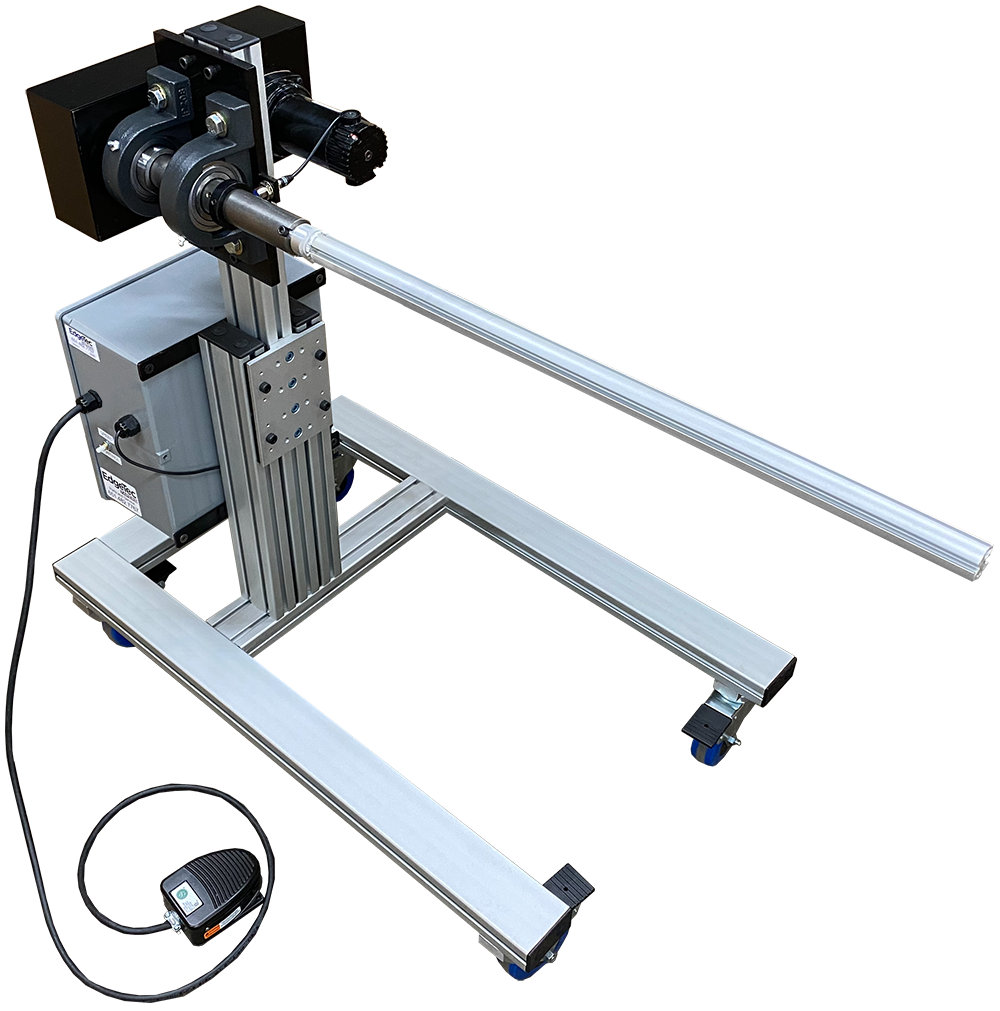

EdgeTec Roll-Up Pro

EdgeTec Roll-Up Machines are variable-speed material rolling machines with shafts individually designed and fabricated for each client’s materials. The EdgeTec Roll-Up is available in two models, a smaller tabletop model, the Roll-Up Lite, and a larger freestanding unit, the Roll-Up Pro.

Both machines are quick to learn and operate. A foot pedal rotates the shaft and rolls the material. The machine’s rotation speed is easily adjusted via a speed control knob.

The shaft of every EdgeTec Roll-Up is fabricated in collaboration with the client and tested with client-provided sample materials to ensure perfect operation and smooth, uncreased materials.

EdgeTec Roll-Up Lite

A small-but-mighty tabletop roller, the Roll-Up Lite is the perfect machine for businesses that need continuous rolling capabilities for light to medium-weight, non-bulky materials like paper or fabric. It can roll multiple posters at once!

EdgeTec Roll-Up Pro

A free-standing unit on lockable casters, the Roll-Up Pro can roll it all — from lightweight posters to heavy weight fabrics and materials.

The Roll-Up Pro also features preprogrammed commands including: a shaft home position for quick material loading; and a slight reverse at the end of rolling, releasing tension for easy removal of the product. Casters on the base of the machine make moving it a breeze!

Shaft Styles

Roll-Up Video Demos

EdgeTec Roll-Up Machine Features

EdgeTec Roll-Up Machine Specifications

Roll Up Pro: Machine Specifications

| Machine Type | A Variable-Speed Material Rolling Machine |

| Working Speed | Max. Shaft Rotation: 389 rotations per minute Max. Material Rolling Speed: ~144 ft/min, dependent on material. Approximately, 6-10 posters per minute. Shaft rotation speed can be adjusted using machine’s speed control knob |

| Rolling Height | 34" - 46" Can be customized upon request. |

| Shaft Length | Customizable from 0.79" - no upper limit. Shafts over 56" may require steady rest. |

| Machine Makeup | Frame: Extruded aluminum High-grade industrial components |

| Machine Weight | 116 lbs |

| Base Machine Dimensions (L x W x H) | 36" x 23" x 40” (Without Shaft) |

| Electrical Requirements | 110 VAC, 50/60Hz, 1 Phase OR 220 VAC, 50/60Hz, 1 Phase |

Roll Up Lite: Machine Specifications

| Machine Type | A Variable-Speed Material Rolling Machine |

| Working Speed | Max. Shaft Rotation: 389 rotations per minute Max. Material Rolling Speed: ~144 ft/min, dependent on material. Approximately, 6-10 posters per minute. Shaft rotation speed can be adjusted using machine’s speed control knob. |

| Rolling Height | Tabletop Height |

| Shaft Length | Customizable between 0.79" - 48" |

| Machine Makeup | Base: HDPE work surface High-grade industrial components |

| Machine Weight | 25 lbs |

| Base Machine Dimensions (L x W x H) | 20" x 13" x 4" (Without Shaft) |

| Electrical Requirements | 110 VAC, 50/60Hz, 1 Phase or 220 VAC, 50/60Hz, 1 Phase |

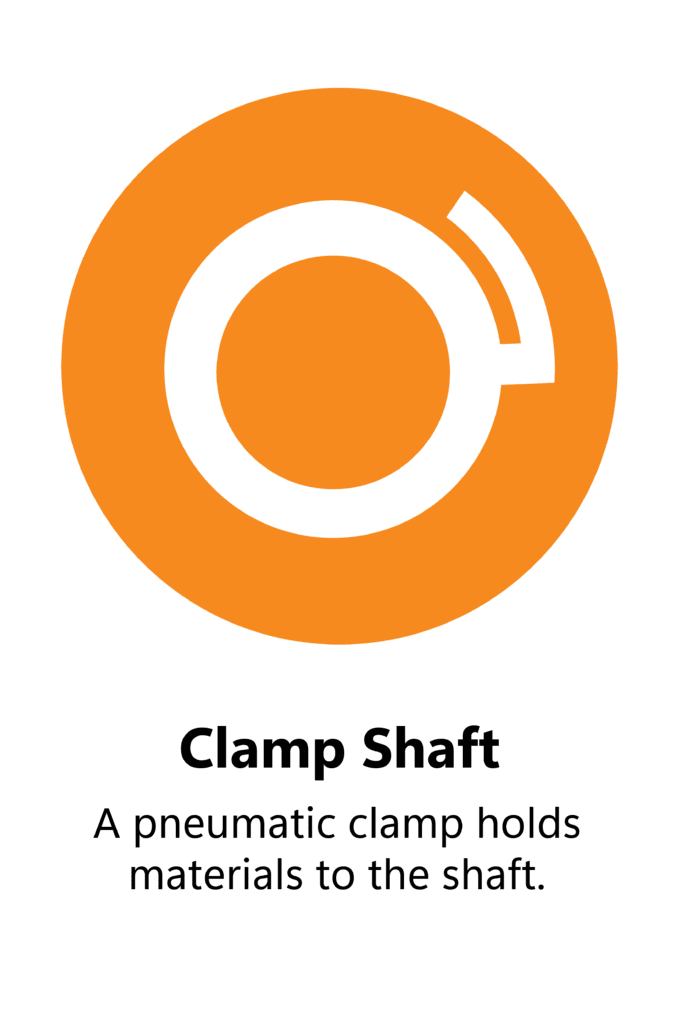

Roll Up: Shaft Categories and Styles

| Extruded Aluminum Profile Shaft | Material is rolled around an aluminum shaft with a specially designed and rounded edge slit to ensure no damage or marring of the rolled material. Slit size is customizable. Extruded Aluminum Profile Shafts are available in a wide variety of diameters. Common diameters include 30mm and 40mm. Available Shaft Styles: Slit or Clamp Shaft Available as an anodized shaft. Anodizing increases durability and eliminates shaft residue on materials. |

| Internal Shaft | Material is rolled inside of the shaft. Internal rolling can produce a tighter, smaller diameter roll and works well for rigid materials. Available Shaft Styles: Slit Shaft Available as an anodized shaft. Anodizing increases durability and eliminates shaft residue on materials. |

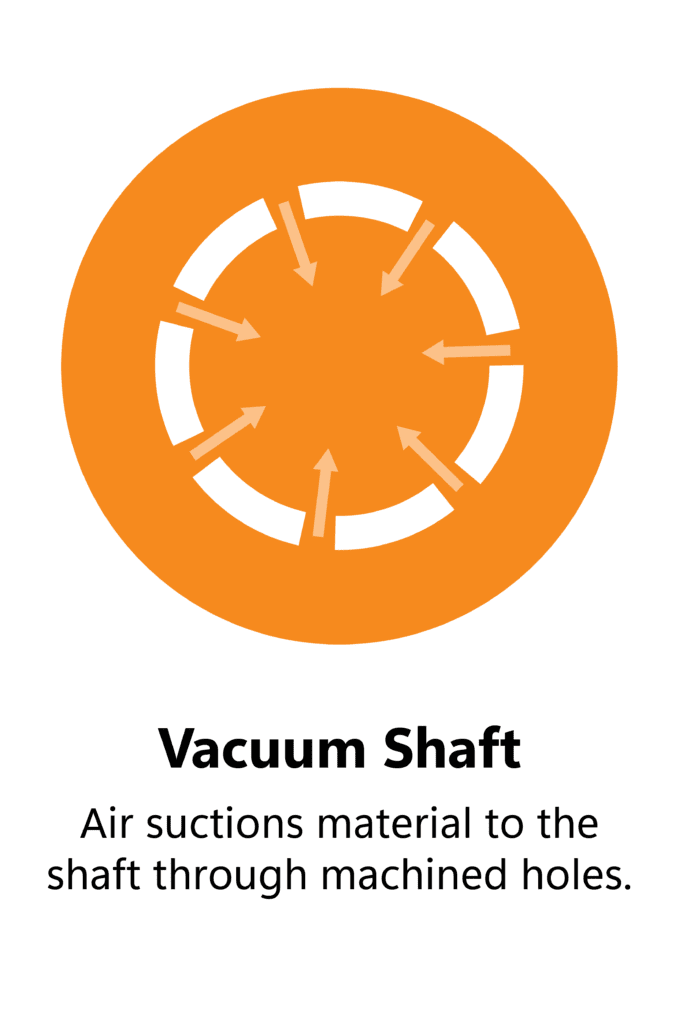

| Round Aluminum Shaft | Aluminum tubing in nearly any diameter and wall thickness is machined with a full or partial slot to roll material. Available Shaft Styles: Slit or Vacuum Shaft Available as an anodized shaft. Anodizing increases durability and eliminates shaft residue on materials. |

| Silicone Coated Shafts | A custom-coated silicone shaft gently grips material without any damage or creases. After rolling, the operator slides a bag or container over the material and the machine releases the rolled product. Good for recycled papers or thick materials. Available Shaft Styles: Friction Shaft |

Roll-Up: Additional Features

| Pneumatic Steady Rest (Pro only) | For long shafts, the steady rest reduces sway and automatically disengages when rolling is finished. |

| Shaft Inserts | For difficult-to-roll materials, a variety of inserts are used to prevent slippage. |

| Additional Customization | Each machine is custom-built. Any modifications to size can be made to fit your needs. |

Request Roll-Up Quote