The Inline L-Clip Taper

The EdgeTec Inline L-Clip Taper is a fully automated case sealing machine for end-of-line use. It is capable of sealing up to 70 boxes a minute, dependent on box size.

A uniquely versatile design, the Inline L-Clip can run one to five tape heads, mounted in practically any position. These tape heads allow users to apply any combination of leading and/or trailing L-Clips of tape and center seam tape. The machine can seal both RSC-style boxes and non-RSC-style boxes. Such as: five-panel folders, full overlap, telescoping, tuck fold,

roll end tuck, and custom boxes.

Accurate and secure tape application means no tape waste. Additionally, a bypass mode keeps production lines moving when certain tape heads are not needed.

Video Demos

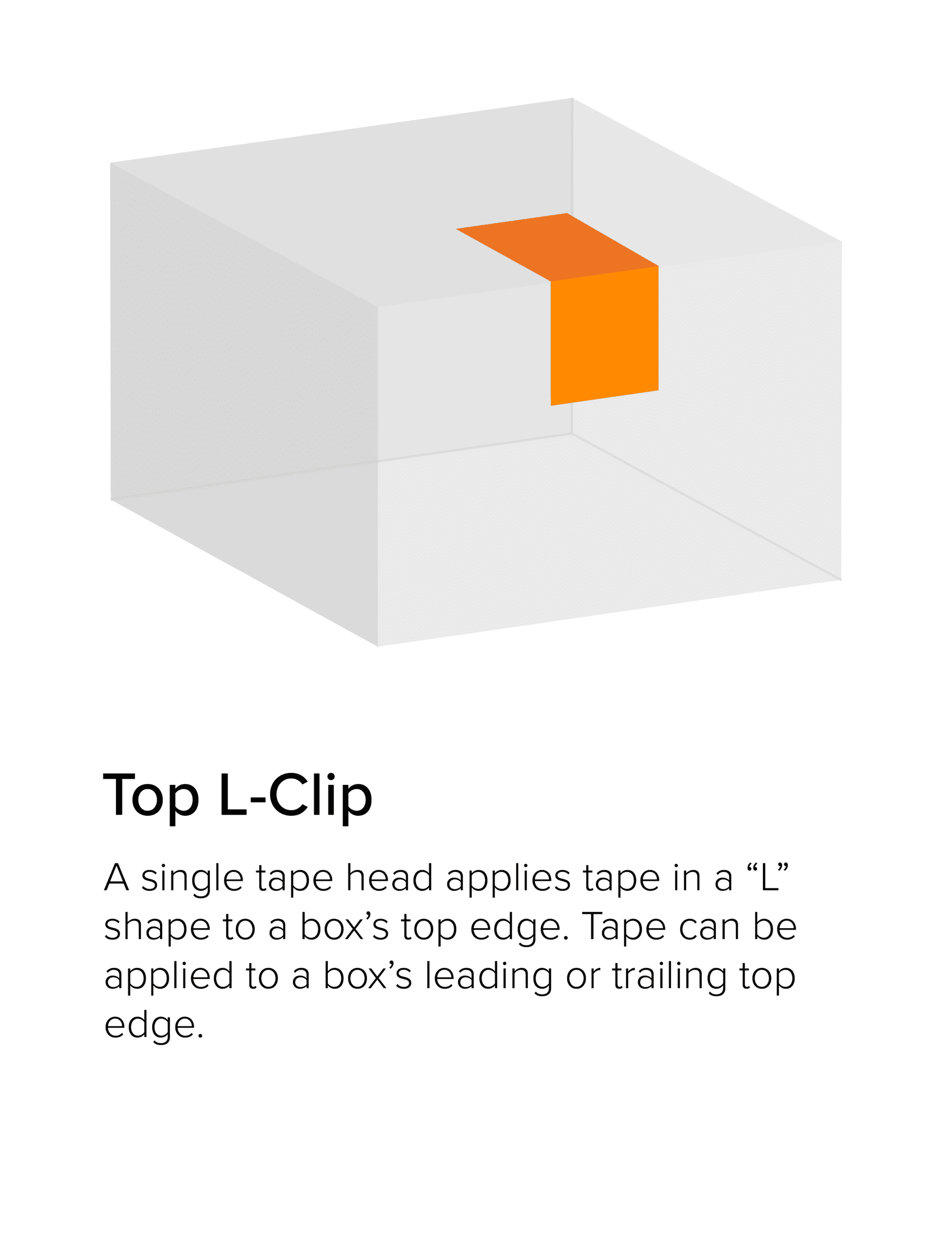

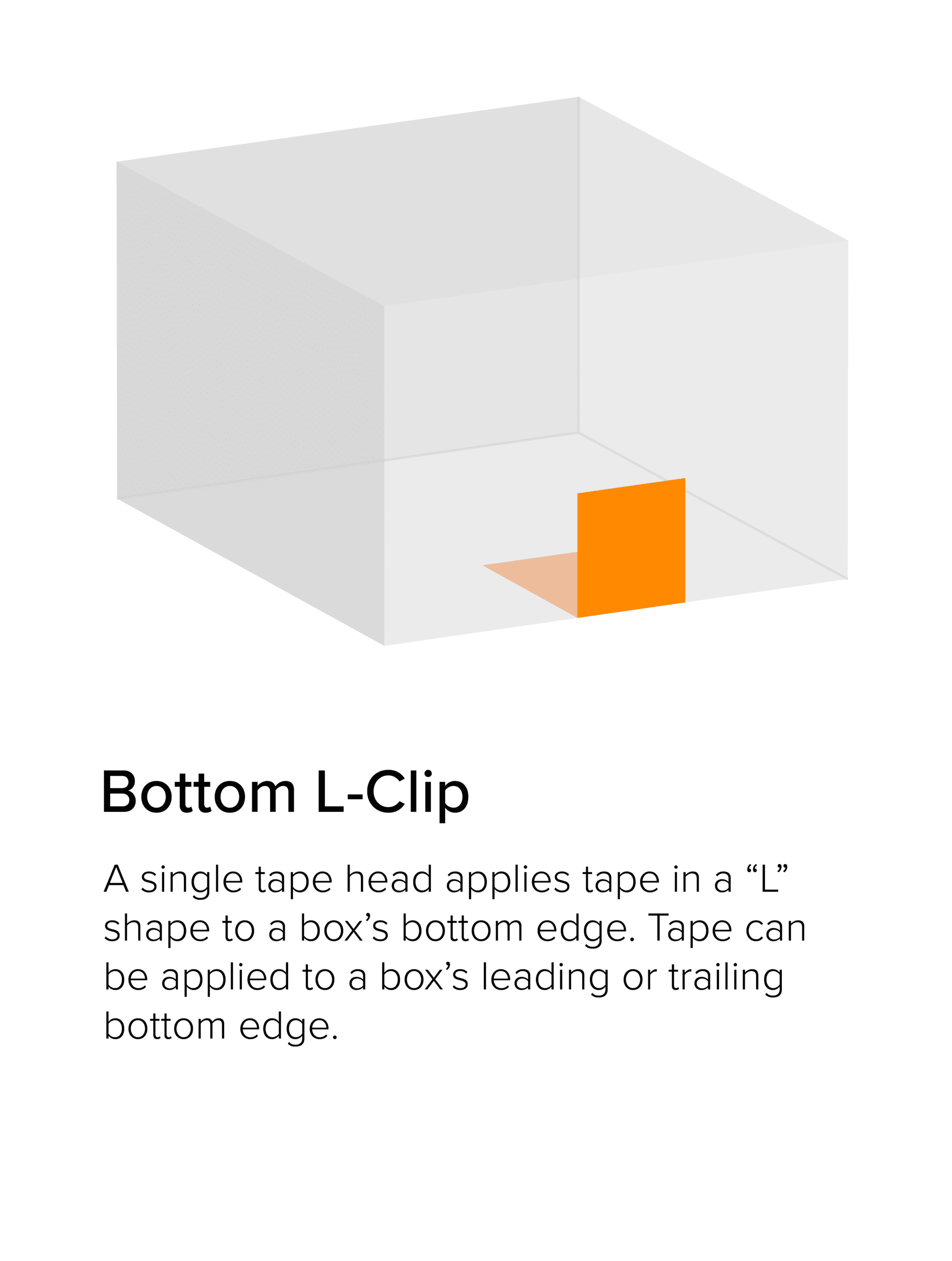

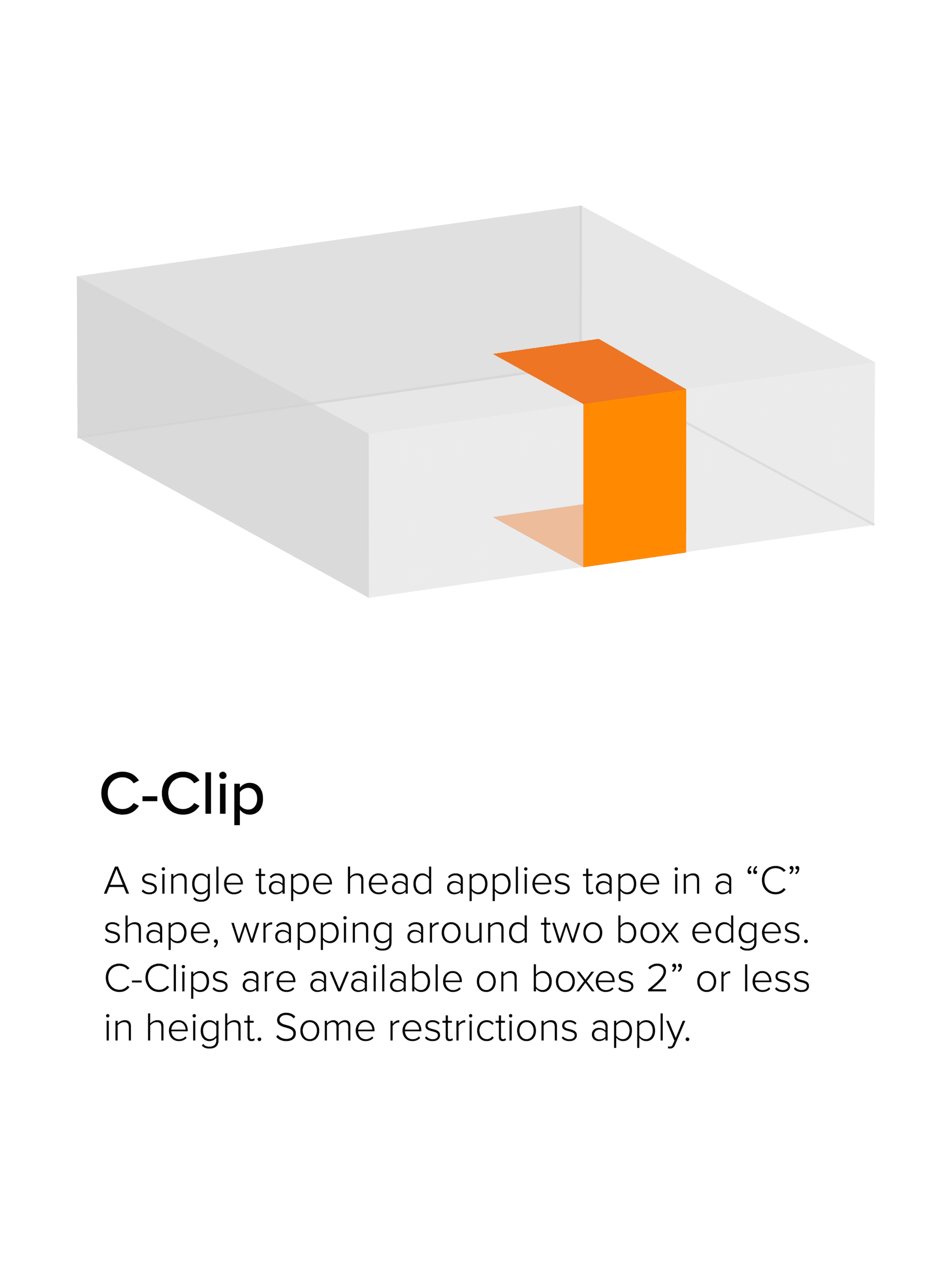

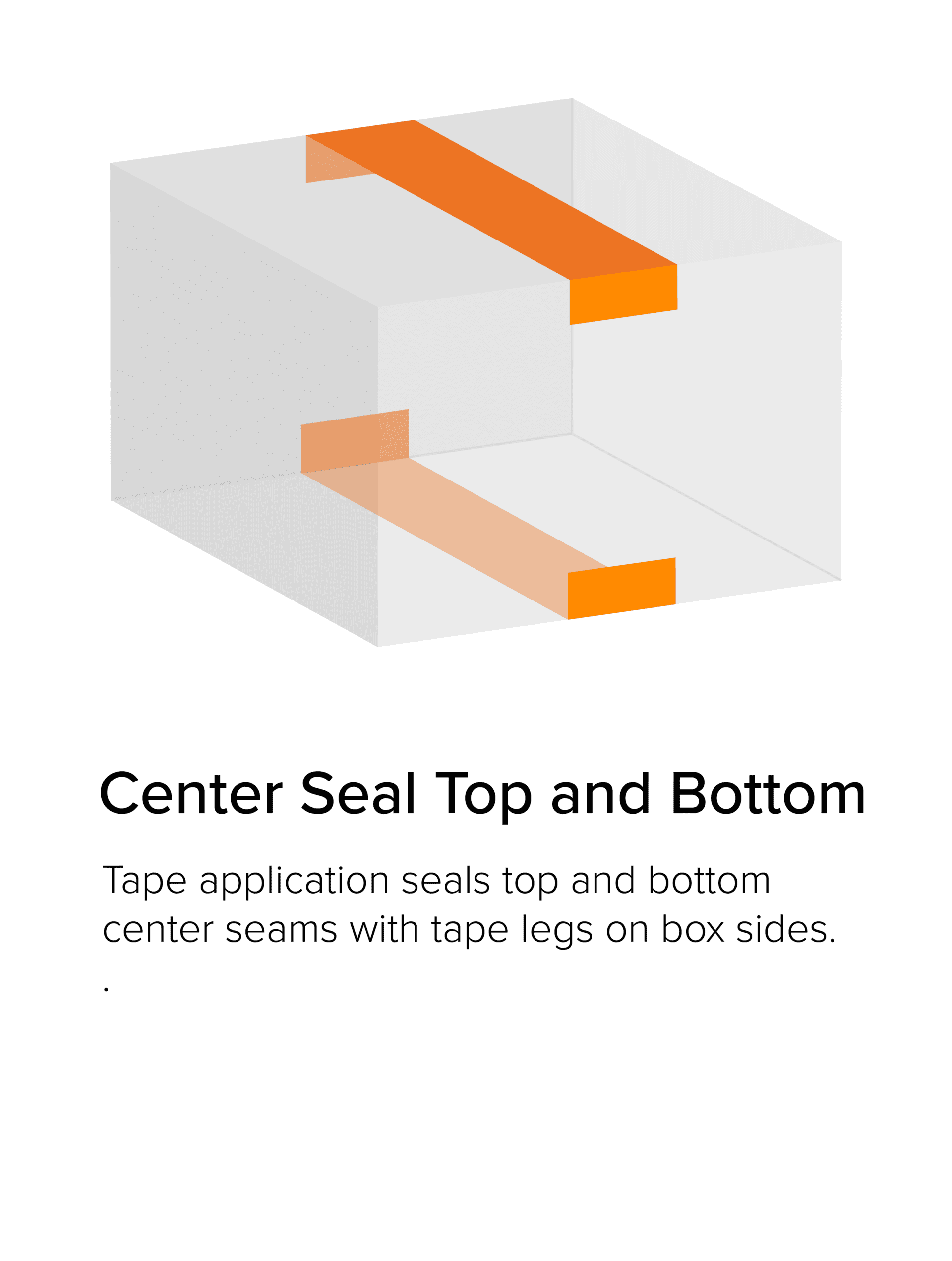

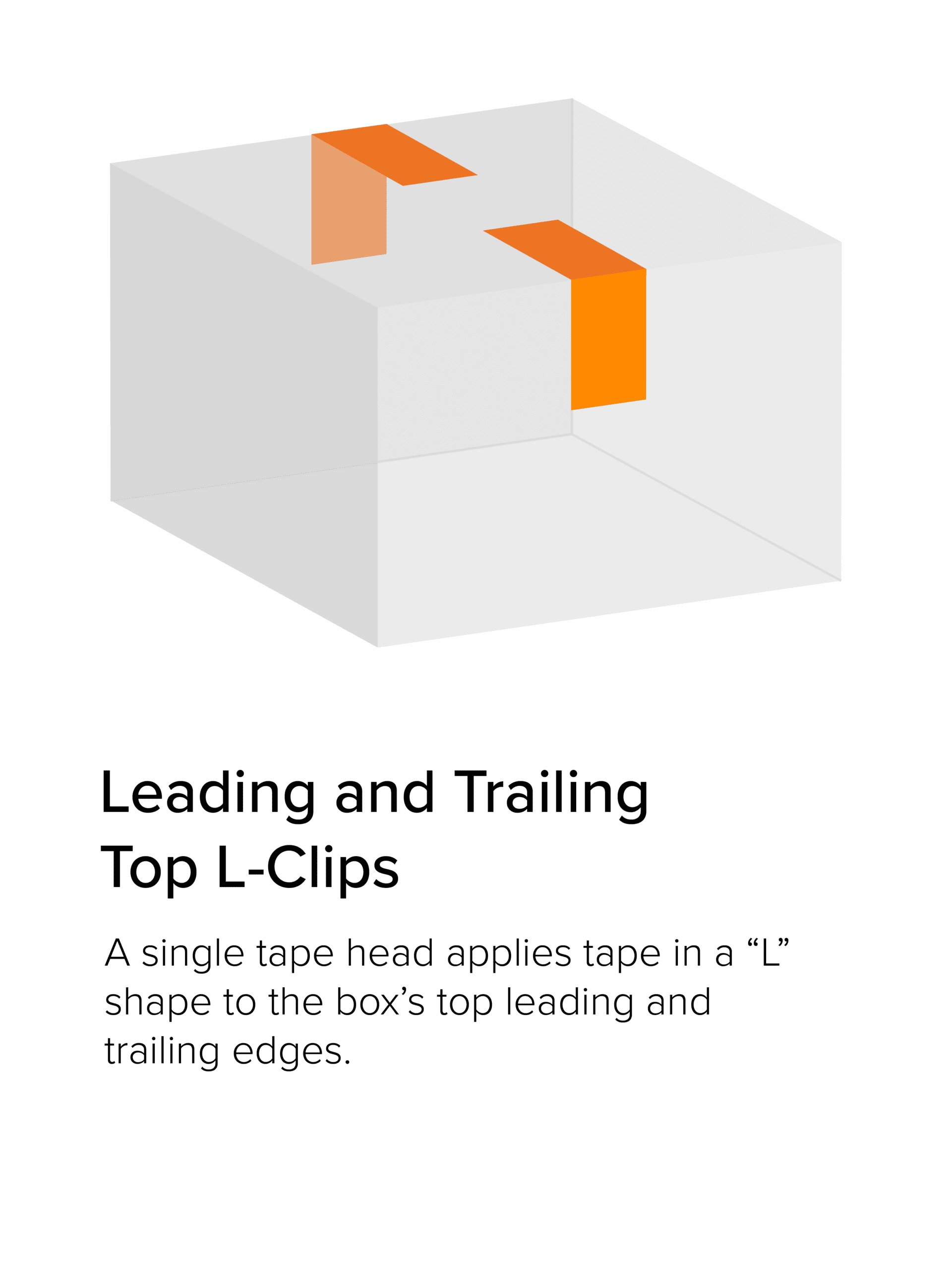

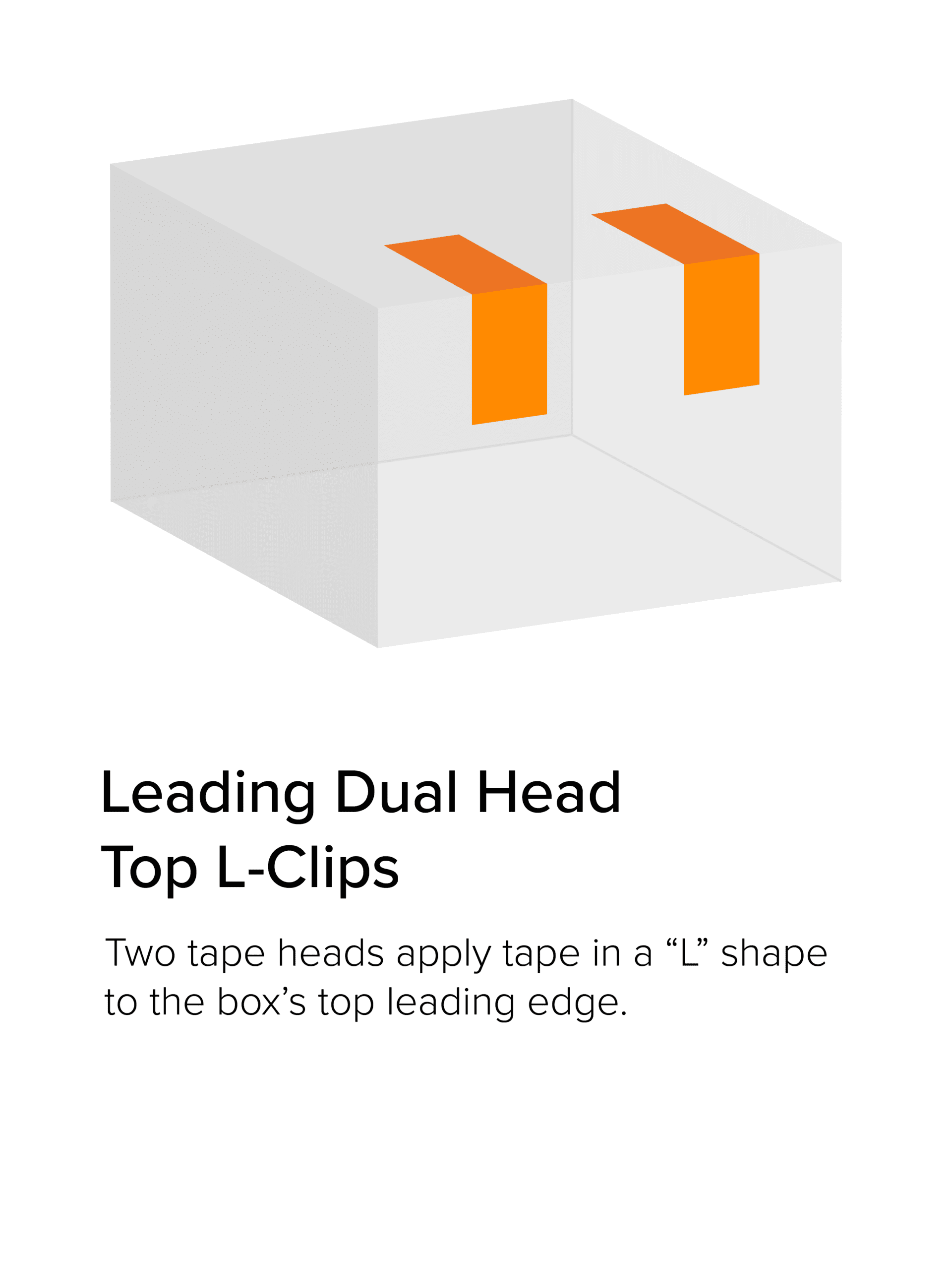

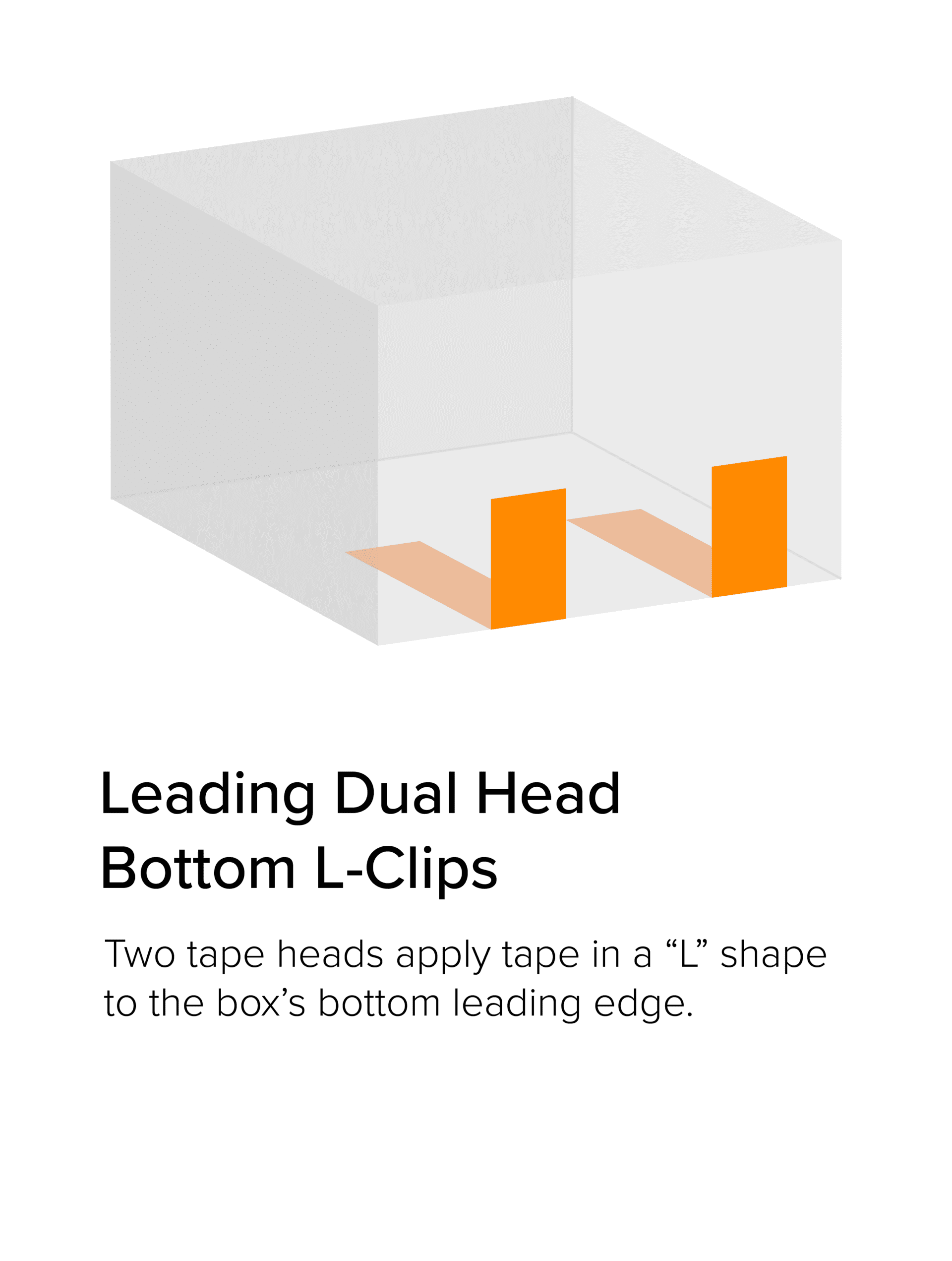

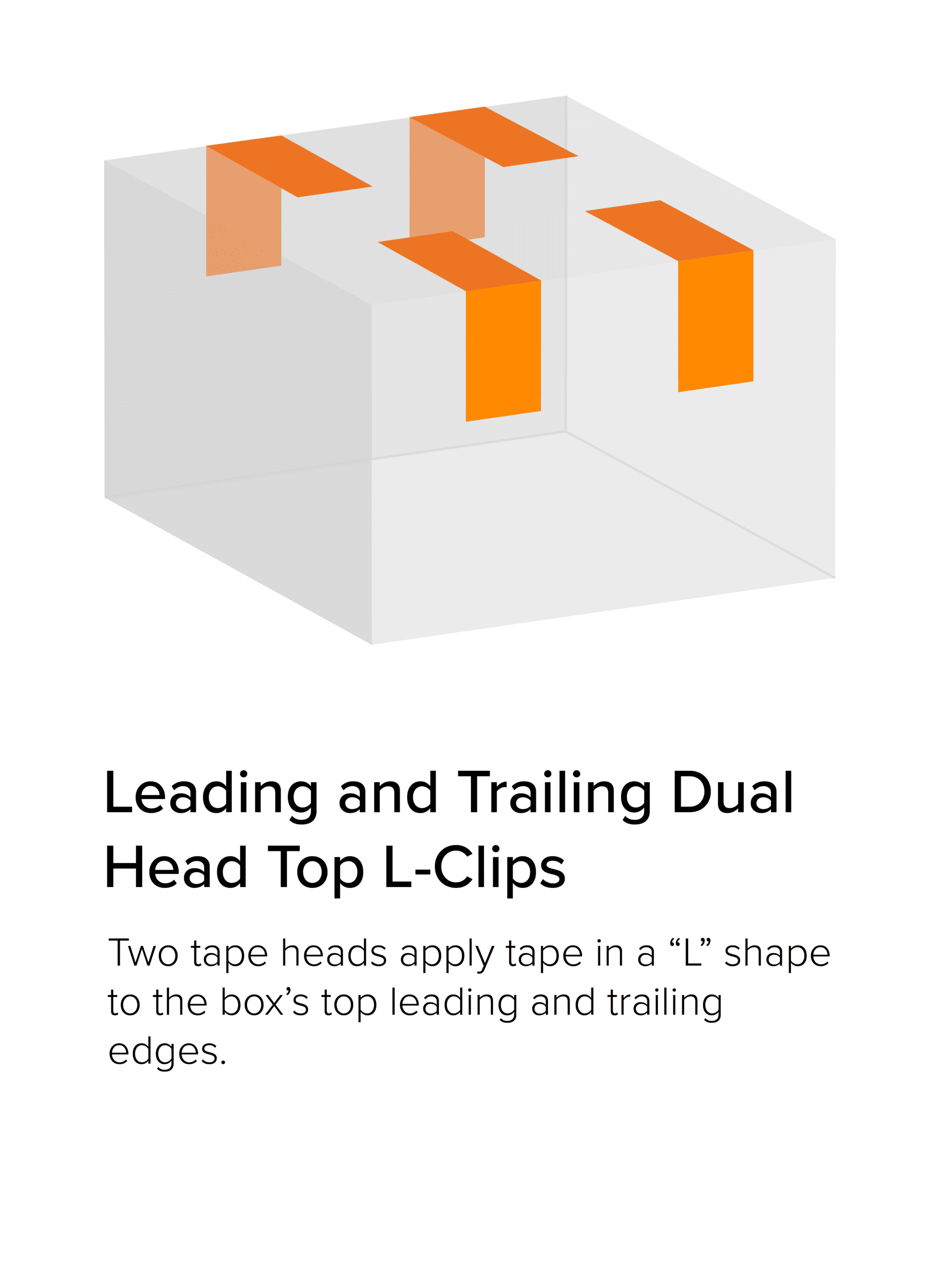

Common Inline Taping Configurations

The EdgeTec Inline L-clip Taper is versatile case sealer. The most common inline taping configurations are shown below. More taping configurations are available, contact us if you’d like to learn more about your taping possibilities!

Key Inline L-Clip Features

Inline L-Clip Specifications

Inline L-Clip: Machine Specifications

| Machine Type | Top or bottom case sealer, uniform side belt drive |

| Machine Makeup | Framework: Industrial strength 12-gauge steel, powder coated for durability, or stainless steel High-grade industrial components |

| Working Speed | 66 ft/min belt speed (Speed can be changed based on customer needs.) |

| Machine Size (L x W x H) | Small Box Machine: 36" x 32.25" x 42” Medium Box Machine: 50.5” x 53.5” 50” Large Box Machine: 66” x 68” x 77” |

| Machine Weight | Small: 350 lbs Medium: 400 lbs Large: 450 lbs |

| Tape Size | Standard: 2” wide pressure sensitive tape, up to 15” diameter rolls Optional: 3” wide tape Optional: Custom tape widths between 1/2” to 2” |

| Tape Heads | 2” Tape: 5.00 inches minimum distance between heads 3” Tape: 5.50 inches minimum distance between heads |

| Tape Styles | Filament, BOPP, Flat Back, PVC |

| Electrical Requirements | 110 VAC, 50/60Hz, 1 Phase or 220VAC 50/60Hz, 1 Phase Power |

| Tape Leg Length | Standard machine applies up to 2.25" on the vertical box wall and a minimum of 2.5" on the horizontal box wall consistently. |

Inline L-Clip: Box Specifications

| Minimum Box Size | Maximum Box Size | |

| Small Box Machine | 4.5" x 4" x 0.875" | ∞ x 19.7" x 19.7" |

| Medium Box Machine | 6" x 5.7" x 0.875" | ∞ x 35.4" x 19.7" |

| Large Box Machine | 12" x 10" x 1" | ∞ x 54" x 10" |

Inline L-Clip: Optional Features

| Infeed/Outfeed Trays | Rollers are extended to assist in the loading and unloading of the machine. |

| All-Electric | The same high-quality taping machine, no compressed air needed. |

| Inline Air Filter | For situations where clean compressed air is not always available. |

| Low Tape Sensor | A sensor monitors tape level and will warn with an indicator light and horn when it’s time to change tape. |

| Hand Crank Counter | Numerical dials are added to the cranks to ensure exact positioning of crank adjustments. |

| Custom Tape Width | Machine adjusted to run a custom tape width. |

Request Inline Taper Quote