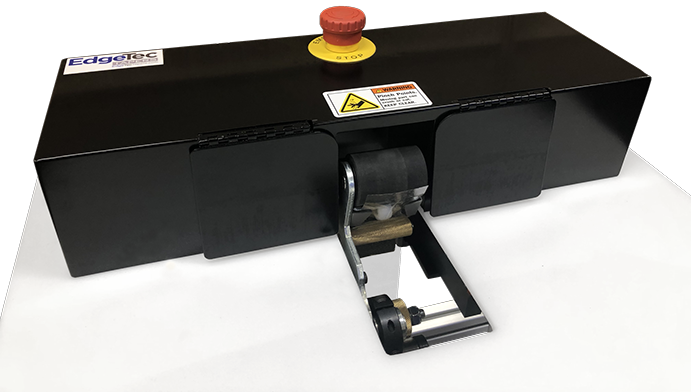

The EdgeTec L-Clip Series

L-Clip 100, L-Clip 200, L-Clip 300

EdgeTec L-Clip machines are semi-automated case sealers designed to seal a wide variety of boxes such as five-panel folders, full overlap, telescoping, tuck fold, roll end tuck top, and custom boxes.

All L-Clips are bump-style machines. The operator presses the box against the machine’s cover to activate the tape head mechanism, automatically applying an “L” clip of tape to the edge of the box.

EdgeTec L-Clip machines can run a wide variety of tape styles, widths, and rolls. Intuitive to use and fast to operate, EdgeTec’s L-Clip allows operators to quickly make consistent, secure corner closures with no tape waste.

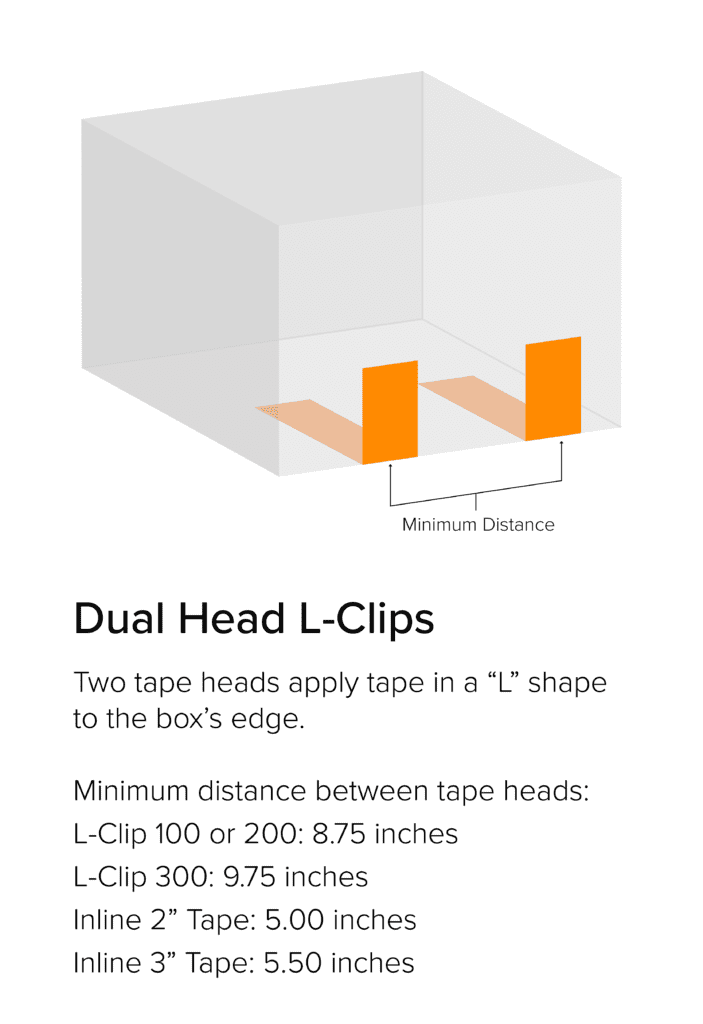

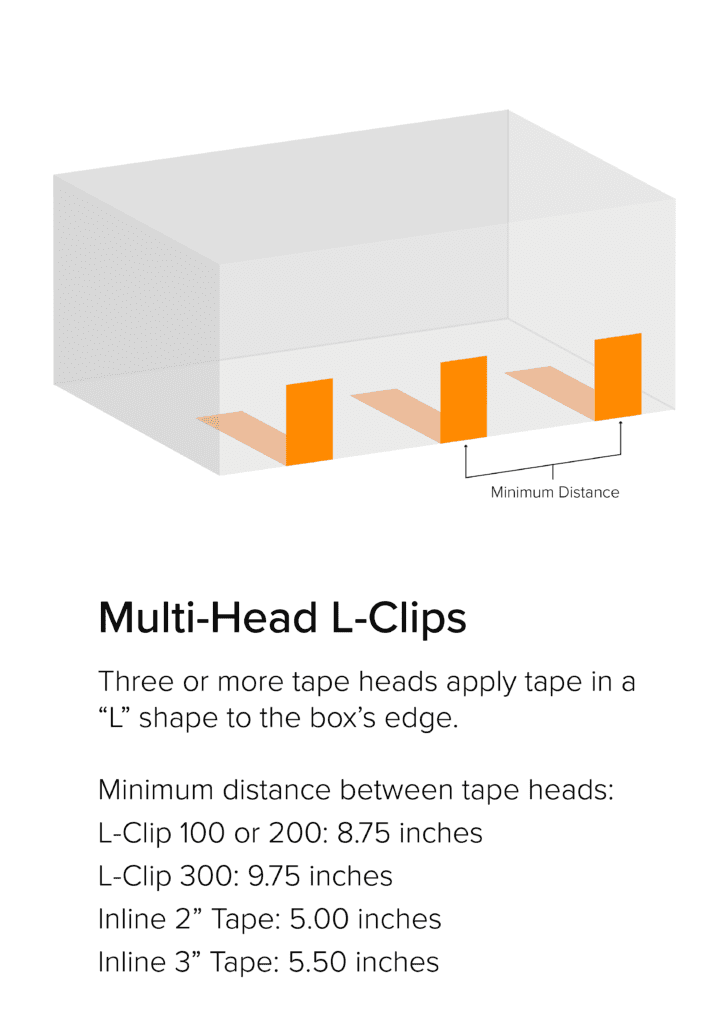

All L-Clips can be configured with one or more tape heads. Multi-head units have a head-to-head minimum distance of 8.75 inches (L-Clip 100 and 200) or 9.75 inches (L-Clip 300.)

L-Clip 100

The L-Clip 100 is designed to run tape widths less than 2 inches.

L-Clip 200

The L-Clip 200 is designed to run a 2 inch tape width.

L-Clip 300

The L-Clip 300 is designed to run a 3 inch tape width.

EdgeTec L-Clip Video Demos

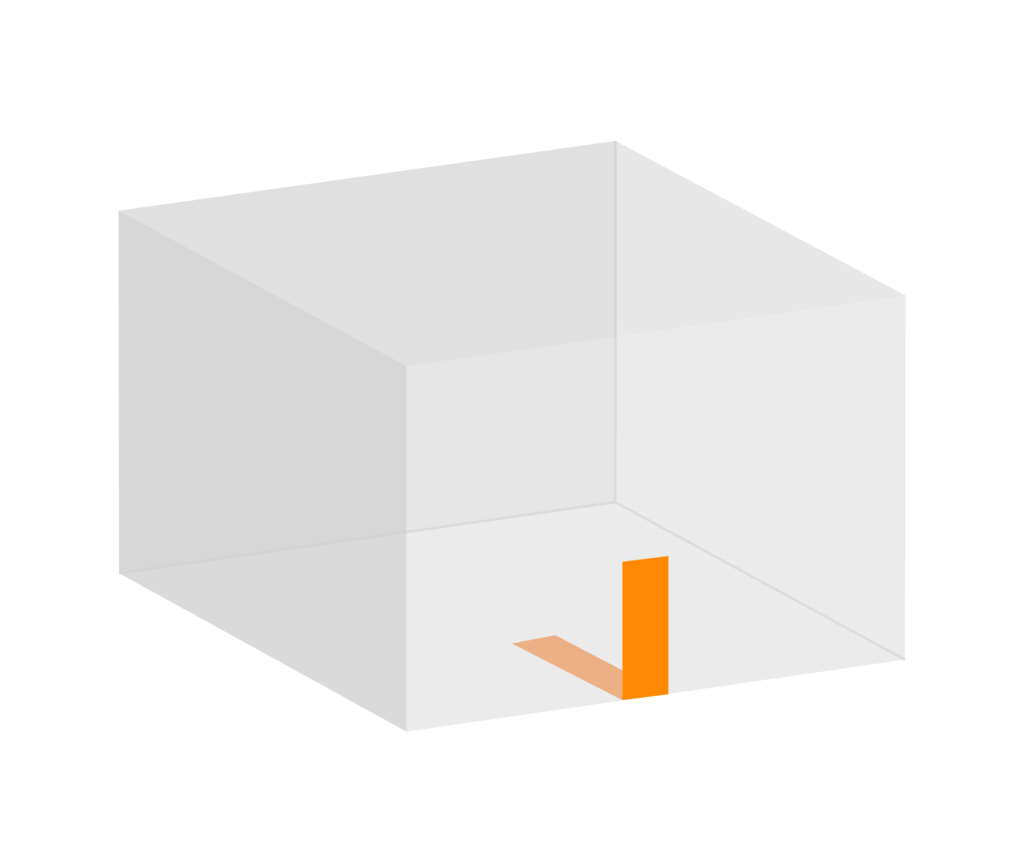

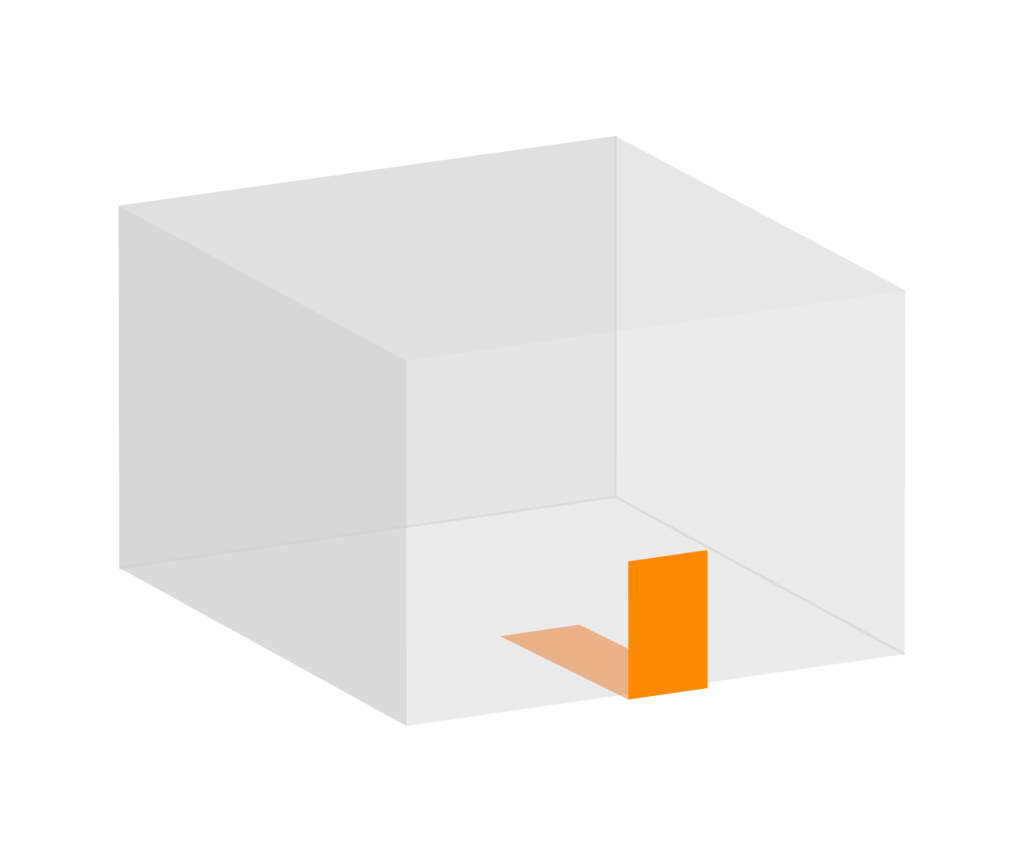

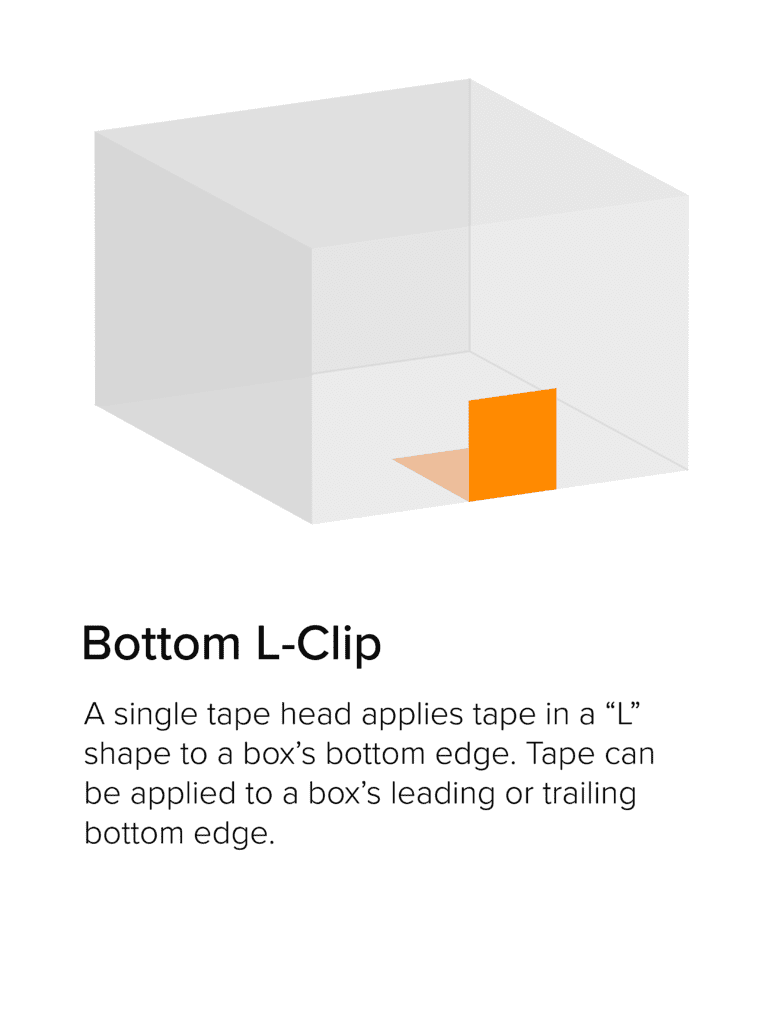

EdgeTec L-Clip Taping Configurations

EdgeTec L-Clip Series Features

No set-up required. Plug and tape!

EdgeTec L-Clip Series Specifications

L-Clip Series: Machine Specifications

| L-Clip 100 | L-Clip 200 | L-Clip 300 | |

| Machine Type | Bump-style L-Clip tape application | ||

| Machine Makeup | Framework: Extruded aluminum Tabletop: .500" thick SANALITE® HDPE Professional-grade industrial components |

||

| Working Height | Tabletop height is adjustable from 30" - 36" | ||

| Tabletop Sizes | Standard Single Head Unit: 21.5" wide x 27" deep Standard Dual Head Unit: 32.5” wide x 27” deep Narrow Single Head Unit: 18.25” wide x 27” deep Tabletops can be customized for your working or packaging space. |

||

| Tape Heads | Multi-head units have a standard spacing of 10.5” between tape heads. Positioning can be customized down to 8.75” or increased with no upper limit. | Multi-head units have a standard spacing of 10.5” between tape heads. Positioning can be customized down to 8.75” or increased with no upper limit. | Multi-head units have a standard spacing of 10.5” between tape heads. Positioning can be customized down to 9.75” or increased with no upper limit. |

| Tape Leg Length | Standard machine applies 2.5" on the vertical box wall and 2.5" on the horizontal box wall with a tolerance of ±0.063". | ||

| Tape Styles | Filament, BOPP, Flat Back, PVC | ||

| Tape Sizes | Tape widths smaller than 2" Accepts 1000 yd (914 m) machine-length rolls. | Tape widths of 2" (48mm) Accepts 1000 yd (914 m) machine-ength rolls | Tape widths of 3" (72mm) Accepts 1000 yd (914 m) machine-length rolls |

| Air Requirements | 90 PSI clean compressed air | ||

| Electrical Requirements | 110 VAC, 50/60Hz, 1 Phase Power OR 220VAC 50/60Hz, 1 Phase Power |

||

L-Clip Series: Box Specifications

| L-Clip 100 | L-Clip 200 | L-Clip 300 | |

| Minimum Box Width | 3.25” | 3.25” | 4.25” |

| Minimum Box Height | Standard Machines: ≥ 2.5” Machines can be customized to work with 0.5” tall boxes. |

||

L-Clip Series: Optional Features

| Box Guide with Flap Closer | A side guide ensures tape is applied to the same location. A spring-loaded arm assists in box folding and holds down the top flap while taping. |

| Low Profile Taping | The vertical tape leg is reduced to apply smaller lengths of tape for boxes less than 2.5” tall. |

| Guarding | Clear Lexan sides and interlocked door are added below tabletop to limit access to machine’s moving components. |

| Ball Table | Allows for easy movement of heavy boxes. |

| Washdown Machine | A machine with a stainless-steel frame designed for full washdown. Ideal for food processing plants. |

| Inline Air Filter | For situations where clean compressed air is not always available. |

| Lag Legs | Swaps out castor wheels with lag point legs made from 11 gauge sheet metal. Tabletop height adjustment stays the same. |

| Variable Tape Legs | Vertical and horizontal tape legs can be adjusted for any combination of 1”, 1.5”, and 2” tape legs. |

| All-Electric | The same high-quality taping machine, no compressed air needed. |

Request L-Clip Quote